The Inprentus team highlighted their mechanical ruling technique to achieve elusive blazed groove shapes for AR waveguides at SPIE AR|VR|MR 2023 conference, held in San Francisco’s Moscone Center from 30th January-1st February.

Revolutionary Blazed Master Waveguide Prototype for AR Applications by Inprentus

Inprentus kick-started the week with Dr. Peter Abbamonte, founder and CSO, presenting a talk titled Mechanically Ruled, Blazed Gratings for AR Waveguides. Using this foundational technique, Inprentus creates triangulated grooves by deforming metallic surfaces with a diamond stylus. He explained that “augmented reality total internal reflection (TIR) waveguides work by using a surface diffraction grating to couple light in and out of the device. The traditional way to tune the spectral response of a grating is by blazing it. However, blazed facets are difficult to fabricate using e-beam lithography techniques, particularly in the sub-wavelength regime (lambda ~500 nm and below)“. The talk was enthusiastically received by members from the AR industry who have relied on alternate lithography techniques and groove shapes until now. He then presented Inprentus’ ground-breaking capabilities in ruling gratings for the AR market in the line density range of 3000-4000 lpmm.

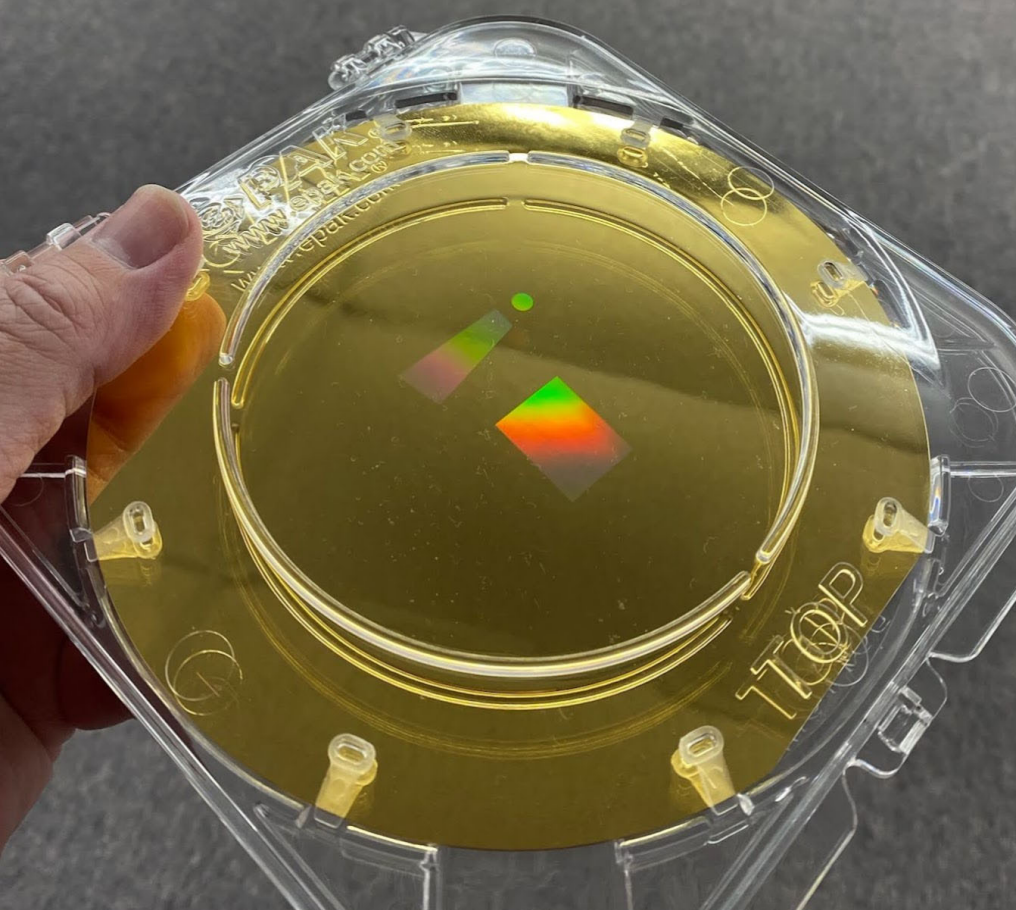

The Inprentus team included Jonathan Manton (CTO), Marty Dugan (VP of Business Development), Dr. Subha Kumar (Product Lead Scientist), and Dr. Sam Gleason (Senior Scientist). Jonathan presented the world’s first mechanically ruled master waveguide mold, consisting of input, turn, and output grating structures, for use in AR headset eyepieces. Jonathan explained that “Inprentus’ waveguide master is ruled on a gold 6-inch wafer and coated with a thin layer of Tantalum to provide an oxide layer to facilitate downstream imprinting processes.”

Subha, Marty, and Jonathan (left to right) at the Inprentus booth at SPIE 2023 AR|VR|XR Conference

The team received feedback that there is an industry-wide gap between the promise of sleek smart glass solutions and current AR glasses. Power-tethering requirements increase bulk, and an important social factor of seeing the wearer’s eyes is currently obscured by the “eye-glow” phenomenon. Inprentus’ ability to make asymmetric, highly tunable blazed structures enable high efficiency and reduced eye-glow. In addition, gratings produced by Inprentus have no write-field limitation and excellent long-range coherence, eliminating the “screen-door effect” common in lithographically made gratings.

Dr. Subha Kumar connected with suppliers on the exhibition floor and observed that ”the conference was extremely useful in providing the pulse on current AR technologies, especially the overview course by Bernard Kress. A variety of industries, domestic and international, require streamlined solutions in place of the current complex mastering and imprinting process. In response, Inprentus continues our commitment to developing partnerships with leading Nanoimprint Lithography (NIL) companies to supply transparent lenses directly to AR customers.”

Inprentus Inc.

Inprentus designs, manufactures, and sells X-ray and EUV diffraction gratings for synchrotron and free electron laser facilities as well as grating masters for augmented reality optics and spectroscopy applications. The company was founded in 2012 to commercialize innovative, nano-scale scribing technology. This technology is a general-purpose approach to high-precision patterning of surfaces and is particularly suited to the manufacture of diffractive optics in which features must be shaped with 0.1-degree angular precision and positioned with nanometer precision over distances of tens of centimeters.

Link to article by WebPost: https://www.webwire.com/ViewPressRel.asp?aId=303846