Inprentus Offers A One-Stop Shop for Augmented Reality Waveguides

Inprentus 3-Grating AR Master Mold, AR Prototype Waveguide with In-Out Coupler for AR Waveguide Applications

Inprentus Advantages

Excellent long-range coherence: Extremely flat wavefronts, no screen door effect

Cut process complexity: Identical process for IC, EPE, and OC gratings

Customization of groove shapes: Alternating groove properties and non-traditional shapes possible

Design to fabrication versatility: A large variety of design solutions can be implemented

Large gratings: Cost does not scale with larger “write” field

High spectral tunability: Wide angular and spectral bandwidth

High optical efficiency: Precision facets with wide range of blaze angles

Efficiency modulation design kit: Pupil expansion strategies available

Ease of volume replication: Proven process pathway to volume replication

Advanced Specifications:

Inprentus-created AR Waveguide prototype (1.9 index) replicated in partnership with Inkron

Versatile: 4'“, 6”, 8” wafers or photomasks

Grating size: No restriction

Pitch Uniformity: < 20 pm

Stray light: < 0.5%

Facet Angles: 0.1 - 85 degrees

Line density: 50-6000 lines per mm

Waveguide Masters

Canonical input, turn and output gratings ruled in gold on 6-inch wafer. The master is typically coated with a thin layer (10–20 nm) of tantalum to provide an oxide layer (Ta2O5), facilitating chemical compatibility for downstream imprinting processes.

High Efficiency Blazed Gratings for AR Waveguides

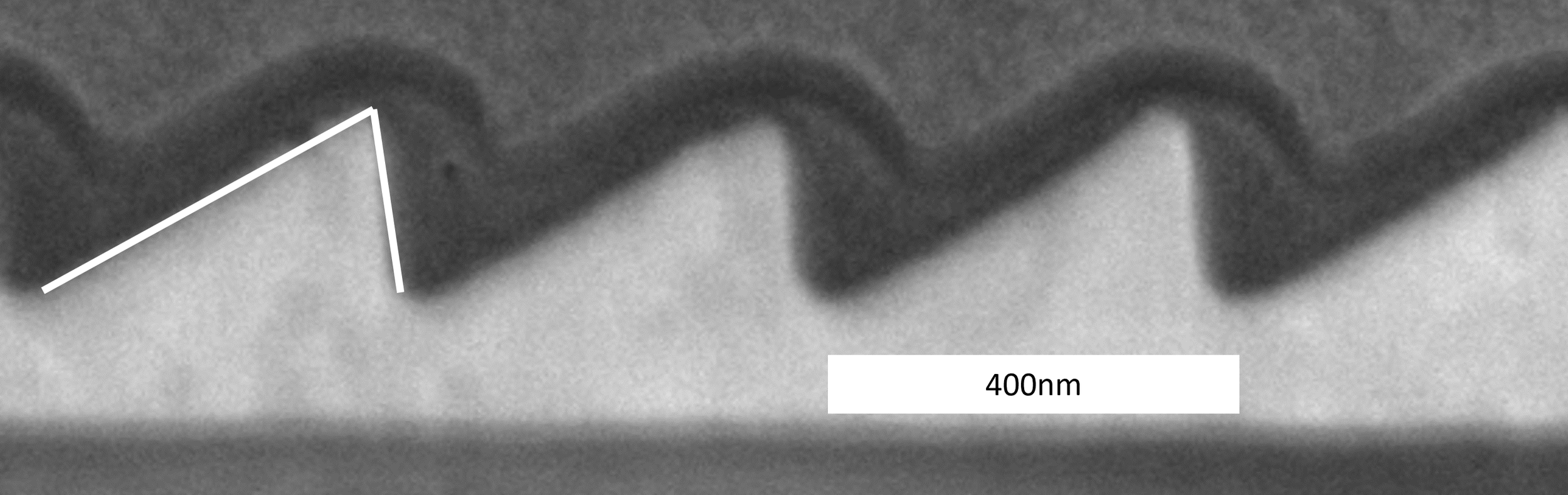

FIB/SEM image of IP-neutral, AR-style grooves at 400-nm pitch, approx. 30-deg blaze and 80-deg anti-blaze angles. The manufactured master is only the bottom-most stratum. The other layers are deposited to enable protective ion-milling for cross-sectional view.

2D Gratings

Inprentus’ ruling technique can produce crossed gratings with lines at arbitrary angles with respect to each other. This achieves pupil expansion using a single grating instead of using turn and output gratings in serial.

How Augmented Reality Waveguides Work

A waveguide consists of 3 gratings - input, turn, and output - on a transparent lens that projects an image into the eye, allowing them to be overlaid onto the real world vision of the user. These waveguide gratings are transferred onto a transparent lens from the "master mold" using a process called imprinting.